These special cameras and enclosures are intrinsically safe in hazardous areas

You can select an explosion-proof enclosure, and then add the camera of your choice, or select an enclosure that includes the camera. Either way, you can get the protection you need when operating in a hazardous environment.

These special explosion-proof systems are intrinsically safe in environments where there are explosive gas or dust. They are designed for use in areas with risk of explosion, such as refineries, gas pipelines, oil tankers, offshore platforms, industrial processes, chemical industries, etc.

The complete explosion-proof camera system includes an HD IP camera. The enclosures are equipped with heating, the housing has operating temperatures between -40° C and + 60° (-40°F / +140°F).

Select enclosures made of stainless steel or solid non-corrosive aluminum construction. Note that these are examples of available enclosures and camera systems. Contact us for more details about all the models available.

Learn more about other enclosures available | IP Camera Systems

Explosion-Proof Enclosures with Cameras

TVIP-EXSHD-XLux

This explosion-proof very low-light IP camera system is in a stainless steel enclosure. The day/night IP camera provides 2-Megapixel resolution at a very low light. The camera includes a 30X zoom lens. The enclosure protects the camera to an IP69 rating.

The stainless steel protects the enclosure in salt water environments. The IP69 ratings guarantee the complete protection against harsh weather and submersion in up to 5 meters of water for 2 hours. Moreover, the IP69 rating allows the device to be cleaned with high-pressure water jets.

This IP explosion-proof IP camera system can operate at temperatures from -60°C to +65°C.

Features

- AISI 316L stainless steel construction

- Camera Full HD 1080p,

- 30x zoom

- Certified ONVIF, Profile S, Profile Q

- Minimum Illumination :

• Color: 0.006lx

• B/W: 0.0006lx - Certifications for use in Zones 1 and 2, IIC T5 and T6 Group (Gas) and in Zones 21

and 22, IIIC T100°C and T85°C Group (Dust) - Marine Certification: Lloyd’s Register Marine Type Approval

- Integrated wiper

- Power supply: 12-24Vdc/24Vac

- IP66 / IP67 / IP68 / IP69

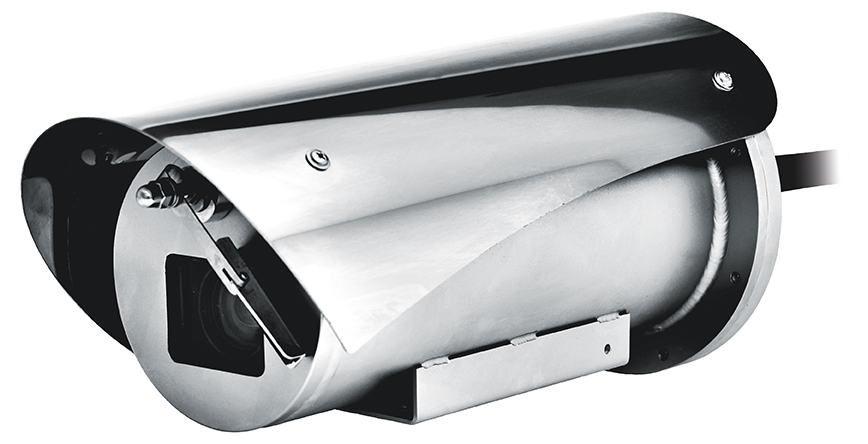

TVIP-EXCSHD

This explosion-proof IP camera system is in a small compact enclosure. The stainless steel enclosure is perfect for use in environments where the atmosphere is potentially explosive due to the presence of inflammable gases or dust, typical of the Oil and Gas, marine or industrial food sectors.

The day/night IP camera provides 2-Megapixel resolution and includes a 10X zoom lens. The enclosure protects the camera to an IP69 rating.

The stainless steel protects the enclosure in salt water environments. The IP69 ratings guarantee the complete protection against harsh weather and submersion in up to 5 meters of water for 2 hours. Moreover, the IP69 rating allows the device to be cleaned with high-pressure water jets.

This IP explosion-proof IP camera system can operate at temperatures from -40°C to +70°C.

Features

- AISI 316L stainless steel construction

- Camera Full HD 1080p

- Select 3X or 10X zoom lens

- Minimum Illumination :

• Color: 0.25lx

• B/W: 0.03lx - Certifications for use in Zones 1 and 2, IIB T6 or T5 Group (Gas) and in Zones 21

and 22, IIIC T85°C or T100°C Group (Dust) - Certification temperature: from -40°C (-40°F) up to +70°C (158°F)

- Marine Certification: Lloyd’s Register Marine Type Approval

- Power supply: 24Vdc/24Vac or PoE+

- IP66 / IP67 / IP68 / IP69

Explosion-Proof Enclosures for Your Camera

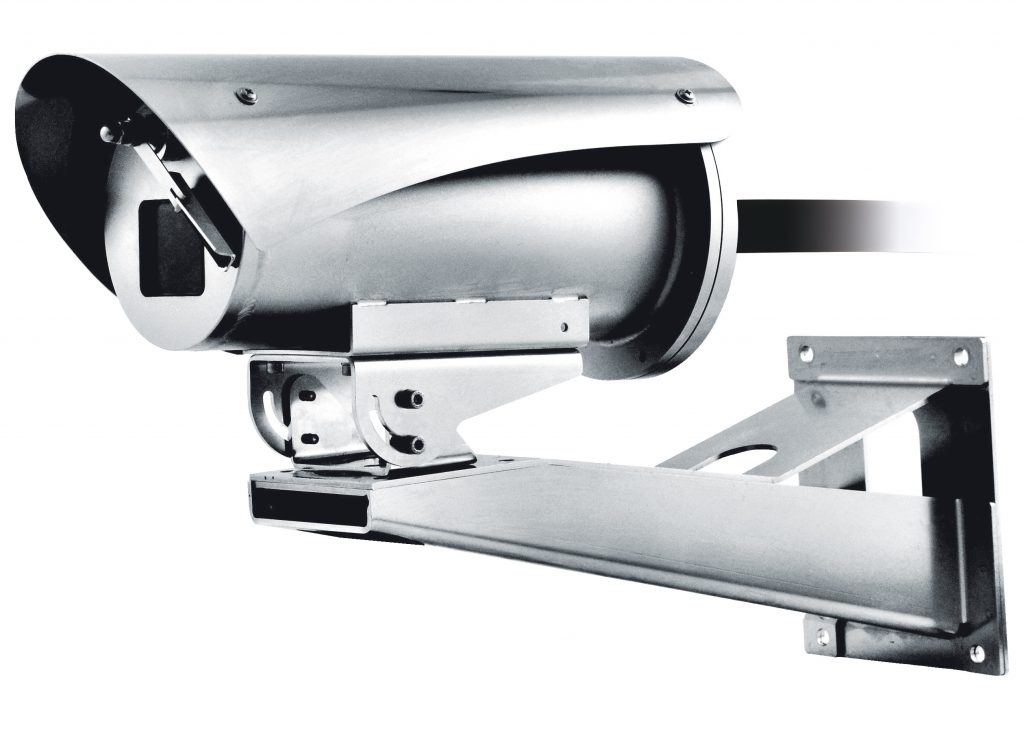

TVIP-M2X

Stainless steel enclosure includes an optional wiper. These explosion-proof housings have been certified and designed to meet the strictest standards regarding installation in potentially explosive environments, given the presence of gas and flammable dust.

The design ensures excellent performance for monitoring critical processes in areas with risk of explosion, such as refineries, gas pipelines, oil tankers, offshore platforms, industrial processes, chemical industries, etc.

Equipped with heating, the housing has the same installation and operating temperatures, comprised between -40° C and + 60° (-40°F / +140°F).

In the version with wiper, M2X is equipped with an integrated telemetry receiver that allows, through the RS485 serial interface, to receive data from the remote control for the activation of the wiper/washer and for switching an eventual external illuminator. The wiring is made easier thanks to the removable connectors on the circuit board. The control board, with removable connectors, is also equipped with an input for the wiper activation through a dry contact. The housing can eventually be controlled by VMS through a video encoder with an RS485 serial port.

Key Features:

- Made of AISI 316L electropolished stainless steel

- Solid non-corrosive aluminum construction

- 2 ¾” NPT threaded holes for use of cable glands or conduit

- Versions with wiper

- Integrated telemetry receiver for the version with wiper

- Supplied with a heater. Sunshield as option

- Power supply: 230Vac, 24Vac or 120Vac

- Environment temperature: -40°C / +60°C (-40°F / +140°F)

TVIP-E2XH

The E2XH housings are made with a strong Anticorodal aluminum die-cast alloy of AISi Mg EN AB- 42000 group. All external components are stove enameled using powder offering an excellent resistance to UV rays, salt-spray, environment polluting substances.

The cylindrical body of the housing (210mm diameter and 400mm length) is closed on opposite sides by two 12 mm thick flanges. The housing is supplied with two holes for the 3/4″ NPT cable glands.

The camera housing is equipped with a heater and optional sunshield. E2XH Ex-proof housing with the same specifications as the E2XH series but fitted with a patented device for the protection of the glass which gives clear vision in dirty environments. The glass protection device consists of a connection flange with the housing, a closing flange and an explosion-proof central body containing a rugged and transparent glass, a motor powered in 24Vac, two windings and a transparent Mylar film, installed just in front of the glass. The motor drives, through four pinions with gear rim, the winding for recovering the dirty Mylar film, while at the same time the other winding installed on the opposite side releases the clean film.

NOTE: the control unit of the glass protection device is not supplied with the product. The transparent Mylar film, 80mm wide and 18m long, allows 350 steps. When the film is dirty, the operator will activate the motor shifting the film to obtain a clean camera picture (the step for allowing the complete shift of the dirty film is about 50mm). The end of the Mylar film will be indicated to the operator through marks printed on the last 50cm of the film.

Key Features:

- Designed to meet the strictest international standards and to operate in hazardous areas

- Solid, non-corrosive die-cast aluminum construction

- 2 holes for cable glands 3/4″ NPT

- Environment temperature: -40°C/+50°C (-40°C/+122°F) with reinforced heater

Resources

For more about the special enclosures, take a look at our article, “What is an Explosion Proof Camera?”.