Reducing Hazardous Situations by Using the Proper Camera Enclosures

An oil rig can be a scary place. On January 22 of 2018, fear turned into reality when an oil rig in eastern Oklahoma exploded. It left many dead and injured. The accident was the result of an uncontrolled release of gas that caught fire.

It is essential to take every precaution to prevent accidents. Flammable contaminants in the air can cause explosions. Gas and dust are the usual culprits. If the concentrations are high enough, it just takes one spark to cause a catastrophic explosion.

This article reviews the certifications and standards that define what type of explosion-proof camera system should be used.

Hazardous Locations

The definition of a hazardous location (HAZLOC) is an area in which the atmosphere contains sufficient quantities of flammable or explosive gases, dust, or vapors.

For example, a dangerous environment could be found on:

- Oil and gas platforms

- Oil & gas drilling rigs

- Oil tankers

- Refineries and petroleum terminals

- Pipelines

- Military facilities

- Chemical and pharmaceutical Factories

- Food processing plants as many solid food and beverage ingredients produce explosive dusts including sugar, starch, flour, spices, tea, grain, and proteins.

The presence of flammable gases or combustible dust doesn’t necessarily define a hazardous area. The quantity or concentration must be sufficient to create the potential hazard. The standards are based on the likelihood of an explosion. It’s all in the statistics. For example, areas that contain gases or dust for an hour per year are less hazardous than an area that contains dangerous gas levels all the time.

The Standards that Rate Explosion Environments

A hazardous area is defined by someone knowledgeable and assigned to mark an area with a specific level of explosion probability. The person who is an Authority Having Jurisdiction (AHJ) can be a Fire Marshal, operational risk assessment engineer, occupational safety authority, or even an insurance underwriter.

Once the area is labeled, all equipment, including IP cameras, must conform to protection methods that mitigate the risk of explosion.

Several standards are used to define hazardous areas. The US, Europe, and the UK have similar specifications. They distinguish various environments by CLASS, Division, and Zones. In the USA, the National Electrical Code (NEC) provides the markings defined by “divisions” and “zones.”

Division 1: is defined as an area where ignitable concentrations of flammable gases, vapors, or liquids can exist most of the time (over 10 hours per year) during normal operation.

Division 2: is defined as an area where ignitable concentrations of flammable gases, vapors, or liquids are not likely to exist under normal operating conditions (under 10 hours per year).

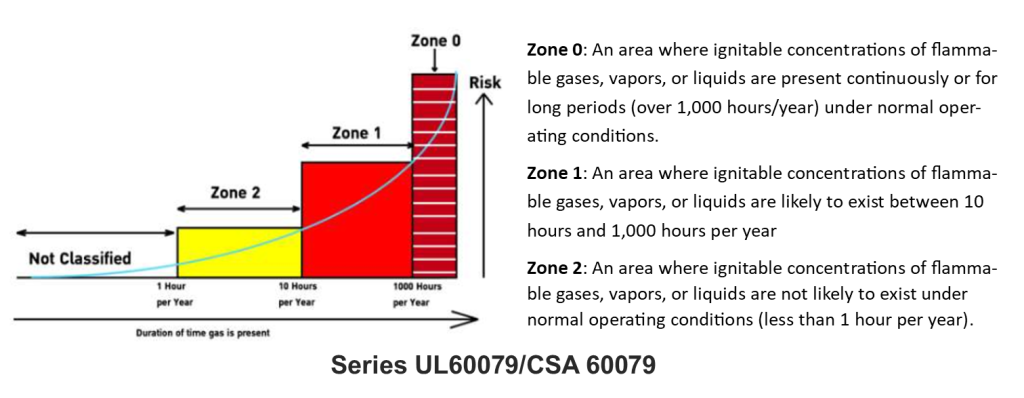

The UL60079 specification uses “zones” to provide more detail about the hazards of an environment:

Zone 0: An area where ignitable concentrations of flammable gases, vapors, or liquids are present continuously or for long periods (over 1,000 hours/year) under normal operating conditions.

Zone 1: An area where ignitable concentrations of flammable gases, vapors, or liquids are likely to exist between 10 hours and 1,000 hours per year

Zone 2: An area where ignitable concentrations of flammable gases, vapors, or liquids are not likely to exist under normal operating conditions (less than 1 hour per year).

Explosion-Proof Enclosures and Cameras

There are explosion-proof enclosures (where you add a camera) and explosion-proof camera systems (that include the IP camera). In many cases, it’s best to purchase a complete system (with the camera) because, according to UL, the cameras must be installed in the enclosure in a UL-approved facility.

The international and European standards don’t have this requirement, so it’s possible to just purchase the enclosure and use your own camera. But it’s important to note that the camera should also be approved for use in this type of application.

IP Camera System Protection Methods

The explosion-proof IP camera system should have the following characteristics to maintain protection:

- The explosion-proof camera system must prevent a spark from reaching the combustible fumes or dust. The enclosure should be sealed, including all the places that cables enter the enclosure.

- The camera system should not allow combustible gases and dust to enter the enclosure. This is usually accomplished by pressurizing the enclosure with inert gas.

- The camera should be designed so there is no source of ignition. This means that the camera should not have a battery that could explode, and the power levels should not be too high.

- If an explosion does occur inside the enclosure, the enclosure should be strong enough to contain the damage. The enclosures are manufactured to be stronger than standard camera enclosures.

Check the Certifications

Make sure that the equipment conforms to the certifications that meet the environmental requirements. The equipment must meet the specific certifications of the country where the equipment is installed.

Here are some of the things to consider for the explosion-proof camera system:

- The enclosure and camera should meet the certification that indicates (Ex d) explosion-proof housing for a potentially explosive environment

- Dust ignition protection (tD A21) for zones 21 – 22.

- The enclosure should prevent excessive temperature that could cause ignition in a gas environment (ATEX: T6).

- The enclosure mustn’t exceed 85° C in a dust environment.

Summary of Explosion Proof Camera Systems

Installing IP camera systems in an explosive environment is challenging. The camera system must be carefully constructed to meet the stringent standards defined by the explosive environment. The potential for an explosion defines the environment. The more an explosive condition is present, the higher the level of protection required. This probability is defined by the person having jurisdiction (AHJ). Check that the explosion-proof certifications meet the hazards of the environment.

To learn more about the best explosion-proof IP camera system, please get in touch with us at 800-431-1658 in the USA or 914-944-3425 everywhere else, or use our contact form.